Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

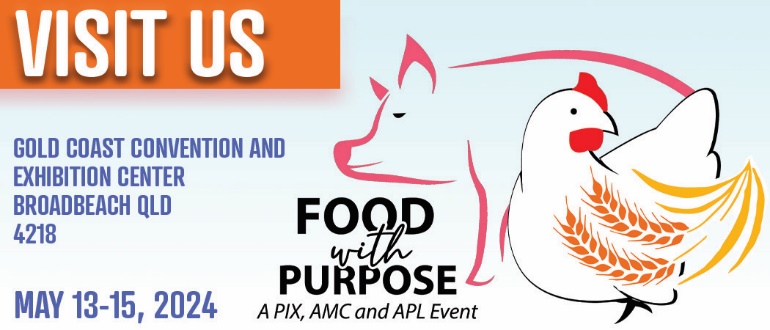

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“What Chad has told me has come true, the Lightning out performed [Competitor] and the other new dies out there hands down!”

“The Lightning resulted in 48% decrease in energy with 19% increase in throughput. Savings $32K!”

“After we installed Pentagons, we saw a 50% increase in production with a finer grind.”

While running the Andritz hammer mill we were having to change the hammers every 1-2 weeks. Once we worked with Jacob’s and change the hammers along with a few other adjustments in the pattern, we were able to get 4-5 weeks of life out of the hammers.

“Jacobs rods resist grooving much better than the other brands I have used in the past.”

“Maintenance sent the following numbers regarding 5 different feeds. Feed 1: 35% Increase in throughput Feed 2: 44% Increase in throughput Feed 3: 42% Increase in throughput Feed 4: 87% Increase in throughput Feed 5: 9% Increase in throughput.”

“I was getting 7 days out of my old supplier’s hammers and I get 10 days from Jacobs’ Hammers! Jacobs is my supplier now!”

“Dale said the Lightning Die he has on mill #2 has 600 hours on it and is still the best running mill!”

“Maintenance Manager said he is now a Jacobs guy as the performance of the die he has been using is getting 30% to 35% more tonnage compared to [Competitor].”

“Ron said the Die works perfect! He wanted 3 tons per hour and got 5 Tons and is still achieving a better pellet. Is happy with the die and it will be Jacobs Exclusively from here on out!”