Pellet Mill Dies

Lightning Strikes Again!

One of our engineers will be onside for the first die installation ensuring all managers and operators are properly trained to maximize pelleting output and energy savings for the specific die purchased.

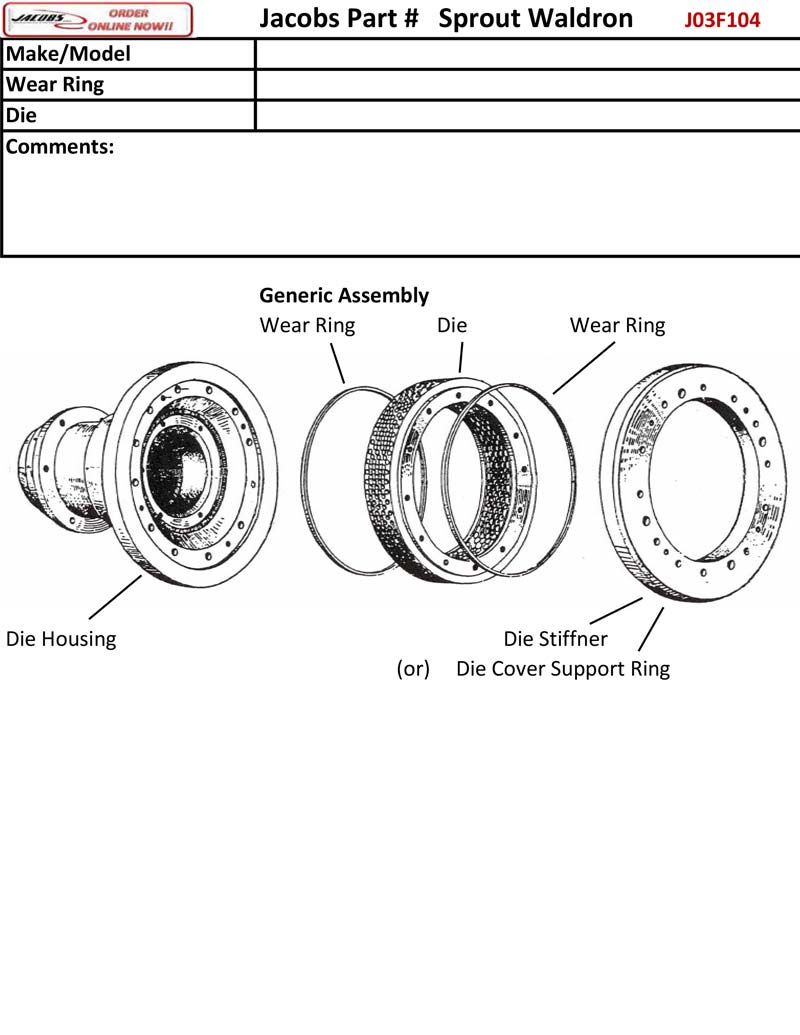

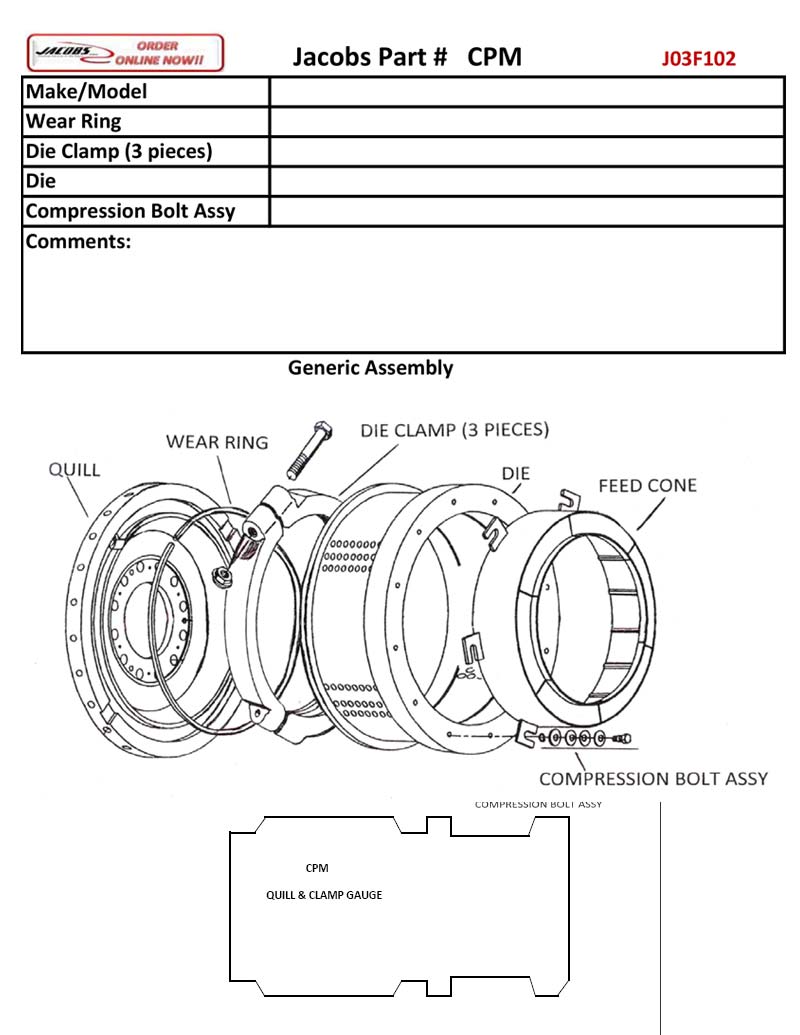

We Can make a Die for Any Brand of Pellet Mill

Jacobs Pellet Mill Dies & Shells will increase efficiency and provide the most tons per hour. Contact us to configure the perfect specifications for your needs!

Because not all pelleting applications have the same die requirements, we offer a variety of steel forgings to satisfy the needs of our customers.

4 unique types of steel forgings

Lightning Dies

J4 Alloy

Hi-Chrome #5

Hi-Chrome

“We installed the new Lightning Die during the first week of January. It has been running great! Once again I am really impressed with this die. It has been a money saver for us and I look forward to running it as long as you keep making them!”

“1st Die ran for 18 Months on 30 TPH mill and ran 172,278 Tons. 2nd Die installed July 7th 2015 and it is over 144,000 tons now and still going!”

“The Lightning Die has increased our production 30%+. The Die has been on for 4,000+ hours and still doing great. We added storage bins, which now was a waste of money as we have increased production and use the raw materials as fast as it comes in. I can’t believe the whole industry doesn’t jump to the Lightning!”

“Very happy with Jacobs Dies! Performing better than [Competitor]. Want another die like the last one.”

“Josh said the Jacobs Die has out performed anything they have used in the past. Very pleased!”