Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

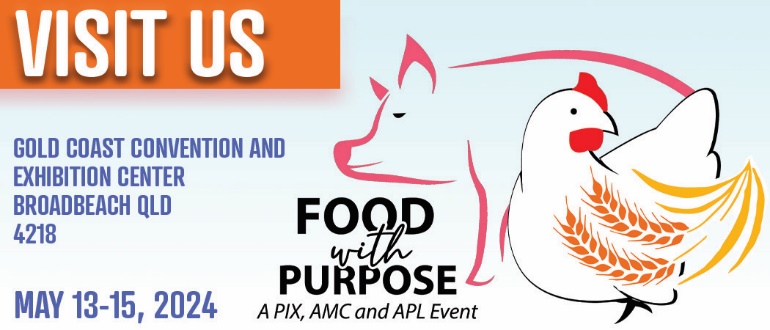

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“Feed flow did increase, we were able to turn them up and get more AMPS on our ground grain elevator. Very satisfied with the Pentagon Hammers. Showed them to sister plant and he is interested in getting a set. I told him I was sold on them.”

“Jacobs rods last a full year with very little grooving, competitors rods needed changed out every 6 months due to excessive grooving.”

“The Jacobs Hammers are in the mill and outlasting the hammers we ran before!”

“Mark said been buying Jacobs Dies for 3 years with no issues for his CPM Mills.”

“Our pelleting process had some inefficiencies, we were seeing rather poor performance from our process and short lifespans from our dies and rolls. . With Jacobs we built a new protocol for our process, from our feed temps, all the way through roll setups. We have been running for several months now and our pelleting production numbers are fantastic, some of our products we increased our performance by over 50%, that translates to multiple tons per week in increased efficiency. We did see an increase in all of our TPH across the board. “

“Both mills running Pentagons. Last sets ran for about 11 months, pushing 13,000 to 14,000 ton per week. 572,000 tons of life on hammers!”

“Josh said the Jacobs Die has out performed anything they have used in the past. Very pleased!”

“Been using Pentagon X2 Holeformance for 3 weeks in Champion Mill. 60 AMPS savings so increased Feed Rate which increased throughput 8%. The Champion capacity is 65 Million and Currently Running at 70-71 Million. Easy to install and fewer spacers! We removed [Brand X] Hammers from a 2nd Mill and replaced with Pentagon X2 Holeformance to get the same savings and increased throughput.”

“Jacobs does a great job of keeping up on our screen needs – price/lead time are always better than other manufacturers.”

“Had Lightning Die on for 18 months on the 30 ton mill and ran 172,278 tons through it. Want one just like it for the 7932 mill. Love them!”