Dry Milling Corn Ethanol Process

Ethanol Process Overview

The beginning stage of ethanol production is to clean the corn, removing any dirt and debris as well as broken kernels. Once the corn is clean it goes through the grinding process. In this stage a hammer mill is used to grind the corn into a fine powder. Once ground, it is mixed with water and enzymes to break down the starch into simple sugars.

From here it is cooked to gelatinize the starch and kill any fungi or bacteria. Then it is cooled and inoculated with yeast, which consumes the simple sugars and produces ethanol and carbon dioxide. Next, is the distillation process which is done to separate the ethanol from the water and other impurities.

The ethanol is further purified through a dehydration process, such as molecular sieve technology. Typically, the final product is denatured with a small amount of gasoline or chemicals to make it unfit for human consumption.

Importance of Hammer Mill Hammers, Screens, and Rods

Benefits

- Quicker installation resulting in more revenue-generating operating time. Most sets have no spacers!

- Longer Hammer life resulting in less replacement costs and downtime.

- Finer corn grinds resulting in less fermenting time! Allows Ethanol to be produced quicker and more efficiently.

- Rods and Screens designed specifically for Ethanol facilities allowing for machine efficiency.

Quality Hammer Mill Products

If durability, efficiency, consistent grinding performance, and ease of installation/removal are important factors when selecting your hammers and rods for your ethanol production processes, our Pentagon systems are the right fit for you! It’s not just a hammer, it’s a system! One part number, one complete kit custom to your hammer mill. Our Pentagon hammers feature Holeformance, which is an elliptical hole for better cleanout and perfect rod contact.

Parts Assistance

Jacobs offers standard hammers and three premium Hammer options for customers to choose from, based on their energy, output, and cost requirements. Our Sales Team is highly trained to discuss the benefits and options of each of the Hammers.

Jacobs' Premium HOLEFORMANCE™

- Allows slight sideways movement

- Increases rod life

- Allows rod to hit the "sweet spot" of the screen

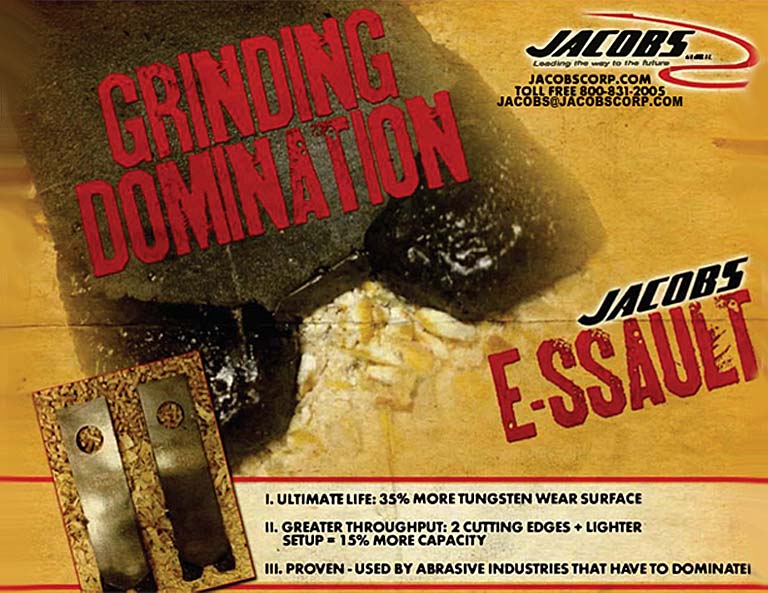

Jacobs' E-ssault

- 35% More Tungsten

- 2 Cutting Edges

- Lighter Setup

- Greater Throughput

- 15% More Capacity

- Proven for Abrasive Use