Hammer Mills for Rendering

How are Hammer Mills Used in the Rendering Process

Hammer mills are often used in the rendering industry to reduce animal by-products such as feathers and bones into smaller particle sizes. The rendering process allows for the conversion of animal waste into valuable products such as animal feed, fertilizers, and biofuels.

Key Features of Hammers

Our Alloy Hammers outperform due to the exact placement and distribution of the tungsten particles during the manufacturing process done only using Jacob's specialized equipment and technical knowledge. Jacobs takes an electro-scan and picture of every lot of our hammers to ensure they have the most advanced and uniform tungsten carbide distribution produced.

Benefits

The Edge Hammer is Jacob’s premium option for animal by-product processing. This hammer was engineered with Pocket Hard-Facing allowing multiple passes of tungsten carbide resulting in a sharper edge and a longer-wearing Hammer. The result is increased productivity in your operations as well as more efficiency with your equipment.

Quality Hammer Mill Parts

Jacobs takes pride in our commitment to producing exceptional wear parts for your hammer mill. The performance and efficiency of your mill is at the top of our list, which is why our unwavering commitment to quality puts us at the top of yours.

Parts Assistance

Our knowledgeable and experienced sales team is on staff to assist with your unique questions, concerns, and goals. Whether you’re a new customer exploring products or a returning customer ready to reorder we are here to help.

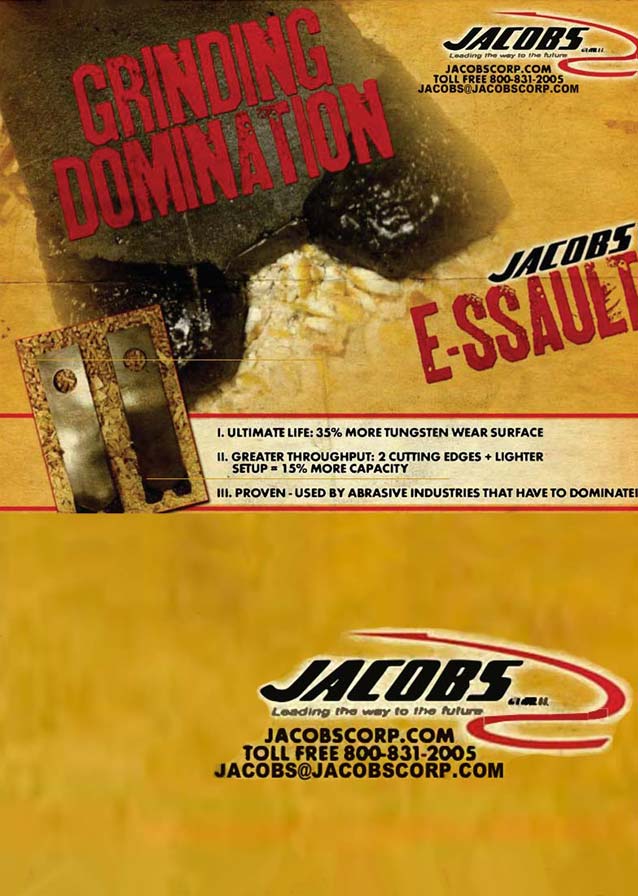

Pictured above are Edge Hammers that were in a plant for 5 weeks. This is 2-3 weeks longer than normally operating time. Outstanding results!

Jacob’s hammers are manufactured specifically for high-performance and well-operated Rendering facilities.

Our Alloy Hammers outperform due to the EXACT placement and distribution of the tungsten particles during the manufacturing process done only using Jacob's specialized equipment and technical knowledge.Jacob’s takes an electro-scan and picture of every lot of our hammers to ensure they have the most advanced and uniform tungsten carbide distribution produced.

Have Questions? Need More Info?

Complete the form below and we will reach out to you.