Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

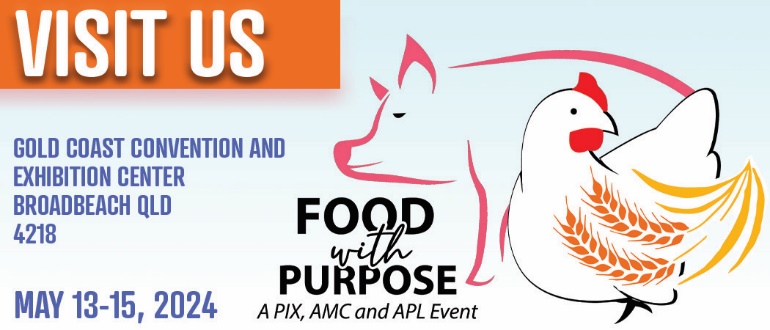

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“The Triple Threat Hammers are working great on my Bliss Mill! Have to order another set! Got about 5.5 months out of them; I won’t go anywhere else!”

“I was getting 7 days out of my old supplier’s hammers and I get 10 days from Jacobs’ Hammers! Jacobs is my supplier now!”

“My operators love the Lightning Die and would kill me if I switched back. The Lightning Die solved many of our pelleting problems!”

“Jacobs does a great job of keeping up on our screen needs – price/lead time are always better than other manufacturers.”

“We recently switched to Pentagon Hammers; the installer said the hammers went on so smooth, they thought something was wrong. Took 20 minutes to install 120 hammers. After a week, the hammers were inspected and there were a few sticking out. Touched them and they fell down. In the next two inspections, all hammers were down.”

“Very pleased with Bad Ax Hammers. Mill has less vibration, first corner 250 to 260 hours, 2nd corner at 180-190 and still going”

“The Pentagon Hammer Set we have in our Roskamp meal grinder is working very well. I’ll be buying at least two more Sets of these hammers for our other machines.”

While running the Andritz hammer mill we were having to change the hammers every 1-2 weeks. Once we worked with Jacob’s and change the hammers along with a few other adjustments in the pattern, we were able to get 4-5 weeks of life out of the hammers.

“I am impressed with Jacobs Hammers, they last a long time!”

“Essault Hammers lasted 11 weeks compared to regular hammers lasting 6 weeks. Ordered 2 more sets. This will be the way to go on hammers from now on!”