Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

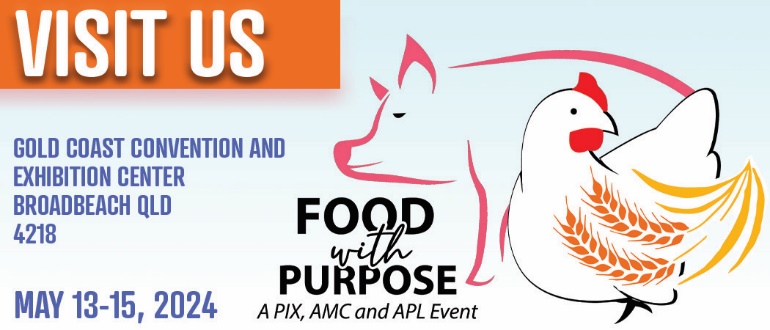

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“Fred wants a die like the last one. Said it is the best die he has ever run!”

“After we installed Pentagons, we saw a 50% increase in production with a finer grind.”

“No one has better Dupps Hammers than Jacobs! We won’t be trying anyone else’s after seeing the quality!”

“It will be Jacobs from here on out! The guys said Jacobs Pentagons were by far the easiest to install and they really enjoy using them versus the others.”

“1st Die ran for 18 Months on 30 TPH mill and ran 172,278 Tons. 2nd Die installed July 7th 2015 and it is over 144,000 tons now and still going!”

“I was getting 7 days out of my old supplier’s hammers and I get 10 days from Jacobs’ Hammers! Jacobs is my supplier now!”

“Essault Hammers lasted 11 weeks compared to regular hammers lasting 6 weeks. Ordered 2 more sets. This will be the way to go on hammers from now on!”

“Extremely pleased with Jacobs Dies. Currently saving 50% more tons on these dies than we were getting with a different supplier!”

“Ron said the Die works perfect! He wanted 3 tons per hour and got 5 Tons and is still achieving a better pellet. Is happy with the die and it will be Jacobs Exclusively from here on out!”

“Mark said been buying Jacobs Dies for 3 years with no issues for his CPM Mills.”