Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

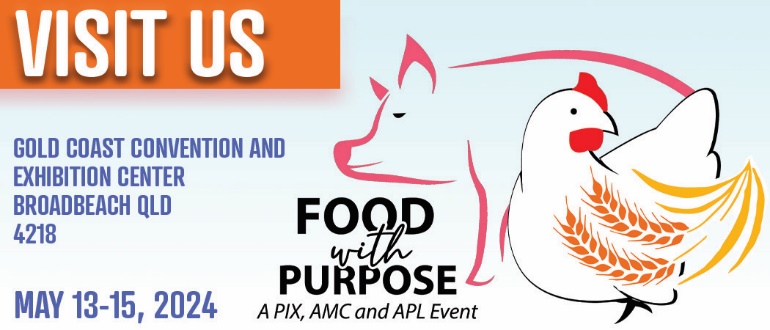

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“Shawn said all parts in the mill plus Die Clamp went in great and looks amazing. The Die Clamp is better than any competitors. Wants a quote on another Die, entire assembly and rolls shells!”

“The Pentagon Hammer Set we have in our Roskamp meal grinder is working very well. I’ll be buying at least two more Sets of these hammers for our other machines.”

After running the Dupps Grindor’s for several months changing the Dupps hammers every 2 days, we ran a trial on the Jacob’s Hammers for the Dupps Grinder and found that we were able to get 5 days of life. We run strictly all beef and bones straight from slaughterhouses.

“Very pleased with Bad Ax Hammers. Mill has less vibration, first corner 250 to 260 hours, 2nd corner at 180-190 and still going”

“Maintenance Manager said he is now a Jacobs guy as the performance of the die he has been using is getting 30% to 35% more tonnage compared to [Competitor].”

“The Lightning Die has increased our production 30%+. The Die has been on for 4,000+ hours and still doing great. We added storage bins, which now was a waste of money as we have increased production and use the raw materials as fast as it comes in. I can’t believe the whole industry doesn’t jump to the Lightning!”

“Very happy with Jacobs Dies! Performing better than [Competitor]. Want another die like the last one.”

“What Chad has told me has come true, the Lightning out performed [Competitor] and the other new dies out there hands down!”

“Been using Pentagon X2 Holeformance for 3 weeks in Champion Mill. 60 AMPS savings so increased Feed Rate which increased throughput 8%. The Champion capacity is 65 Million and Currently Running at 70-71 Million. Easy to install and fewer spacers! We removed [Brand X] Hammers from a 2nd Mill and replaced with Pentagon X2 Holeformance to get the same savings and increased throughput.”

“I am impressed with Jacobs Hammers, they last a long time!”