Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

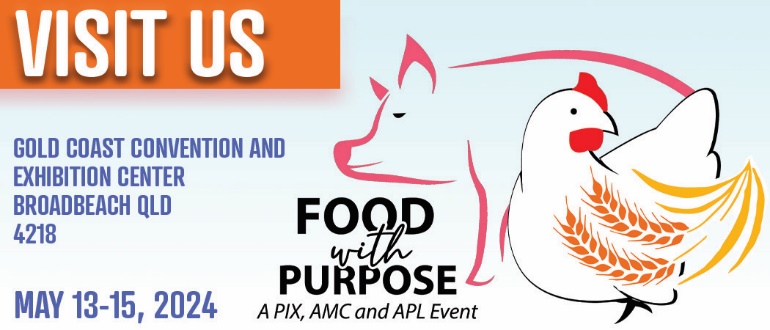

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“Gold star for pentagons! We are getting the best grind we have ever had and are happy about that!”

“The Pentagon Hammer Set we have in our Roskamp meal grinder is working very well. I’ll be buying at least two more Sets of these hammers for our other machines.”

“Lightning Die has better PDI by 15%, designed right for the DDG Formulation. Very impressed with quality up and AMP draw 15% less.”

“The Triple Threat Hammers are working great on my Bliss Mill! Have to order another set! Got about 5.5 months out of them; I won’t go anywhere else!”

“There is no comparison out there to the durability of Jacobs Hammers, they’re amazing. Hardfacing is so good, the hammers are not wearing out. Only buying Jacobs Hammers!”

“Mark said been buying Jacobs Dies for 3 years with no issues for his CPM Mills.”

“Both mills running Pentagons. Last sets ran for about 11 months, pushing 13,000 to 14,000 ton per week. 572,000 tons of life on hammers!”

“Feed flow did increase, we were able to turn them up and get more AMPS on our ground grain elevator. Very satisfied with the Pentagon Hammers. Showed them to sister plant and he is interested in getting a set. I told him I was sold on them.”

“Josh said the Jacobs Die has out performed anything they have used in the past. Very pleased!”

“Very pleased with Bad Ax Hammers. Mill has less vibration, first corner 250 to 260 hours, 2nd corner at 180-190 and still going”