Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

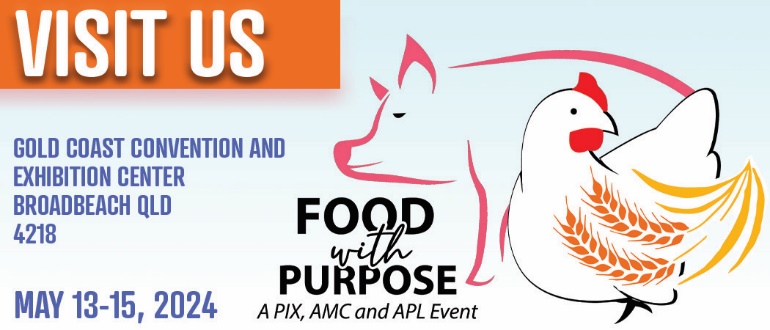

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“1st Die ran for 18 Months on 30 TPH mill and ran 172,278 Tons. 2nd Die installed July 7th 2015 and it is over 144,000 tons now and still going!”

“No one has better Dupps Hammers than Jacobs! We won’t be trying anyone else’s after seeing the quality!”

“Both mills running Pentagons. Last sets ran for about 11 months, pushing 13,000 to 14,000 ton per week. 572,000 tons of life on hammers!”

“We installed the new Lightning Die during the first week of January. It has been running great! Once again I am really impressed with this die. It has been a money saver for us and I look forward to running it as long as you keep making them!”

“Very pleased with Bad Ax Hammers. Mill has less vibration, first corner 250 to 260 hours, 2nd corner at 180-190 and still going”

“I was getting 7 days out of my old supplier’s hammers and I get 10 days from Jacobs’ Hammers! Jacobs is my supplier now!”

“We love your Hammers! They are more durable than the competitors, and that’s why we’re now using Jacobs Rod!”

“Been using Pentagon X2 Holeformance for 3 weeks in Champion Mill. 60 AMPS savings so increased Feed Rate which increased throughput 8%. The Champion capacity is 65 Million and Currently Running at 70-71 Million. Easy to install and fewer spacers! We removed [Brand X] Hammers from a 2nd Mill and replaced with Pentagon X2 Holeformance to get the same savings and increased throughput.”

“Jacobs rods resist grooving much better than the other brands I have used in the past.”

“Fred wants a die like the last one. Said it is the best die he has ever run!”