Hammer mill and Pellet Mill Replacement Parts

A Worldwide Leader in Replacement Parts for Mills Since 1934.

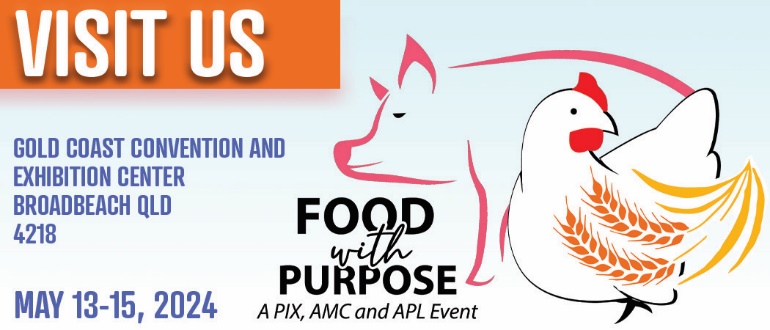

Upcoming Events

Our Mill Products & Services

Hammer Mills

Hammers

Rods and Spacers

Screens

Pellet Mills

Dies

Roller Shells

Die & Shell Rework

“The Triple Threat Hammers are working great on my Bliss Mill! Have to order another set! Got about 5.5 months out of them; I won’t go anywhere else!”

“It will be Jacobs from here on out! The guys said Jacobs Pentagons were by far the easiest to install and they really enjoy using them versus the others.”

“The Triple Threats are living up to the talk on our Bliss Mill. [Competitor] hammers are needing replaced and Jacobs’ barely looked used!”

“We installed the new Lightning Die during the first week of January. It has been running great! Once again I am really impressed with this die. It has been a money saver for us and I look forward to running it as long as you keep making them!”

“Josh said the Jacobs Die has out performed anything they have used in the past. Very pleased!”

“Shawn said all parts in the mill plus Die Clamp went in great and looks amazing. The Die Clamp is better than any competitors. Wants a quote on another Die, entire assembly and rolls shells!”

“Extremely pleased with Jacobs Dies. Currently saving 50% more tons on these dies than we were getting with a different supplier!”

“After we installed Pentagons, we saw a 50% increase in production with a finer grind.”

“Fred wants a die like the last one. Said it is the best die he has ever run!”

“What Chad has told me has come true, the Lightning out performed [Competitor] and the other new dies out there hands down!”